G-Series

Griffco G-series Griffco diaphragm back pressure valves and diaphragm pressure relief valves are designed to enhance the performance of chemical (dosing) pump systems by applying a continuous back pressure to the chemical feed pump, while also acting as an anti-syphon valve. The robust construction ensures reliability in heavy-duty industrial applications, among others. The G-series enables a higher flow compared to the M-series.

Liquid contact materials:

- PVC

- CPVC

- PP

- PVDF

- PTFE

- Halar®

- SS 316L

- Alloy 20

- Hastelloy® C

Available sizes:

- 1/2″ to 4″ or DN 15 to DN 100.

Features and benefits:

- High reliability at an affordable price

- Anti-syphon function

- Solid, robust, (machined) construction

- Wide range of materials

- Flanged-, union-, threaded- and glue/weld options

- Injection moulded Noryl top with integrated pressure lock

- SS 316L metall valvetop option

- Moulded PTFE / EPDM-diaphragm

- Several materialoptions for diaphragms

- Long lifetime diaphragm

- Pressure adjustable up to 25 bar

- 4 optional pressure ranges (springs)

- Connection sizes from 1/2“ up to 4” of DN15 up to DN100

- Tamper proof set screw

- High temperature option up to 150˚C

- Factory adjusted pressure or on site adjustable

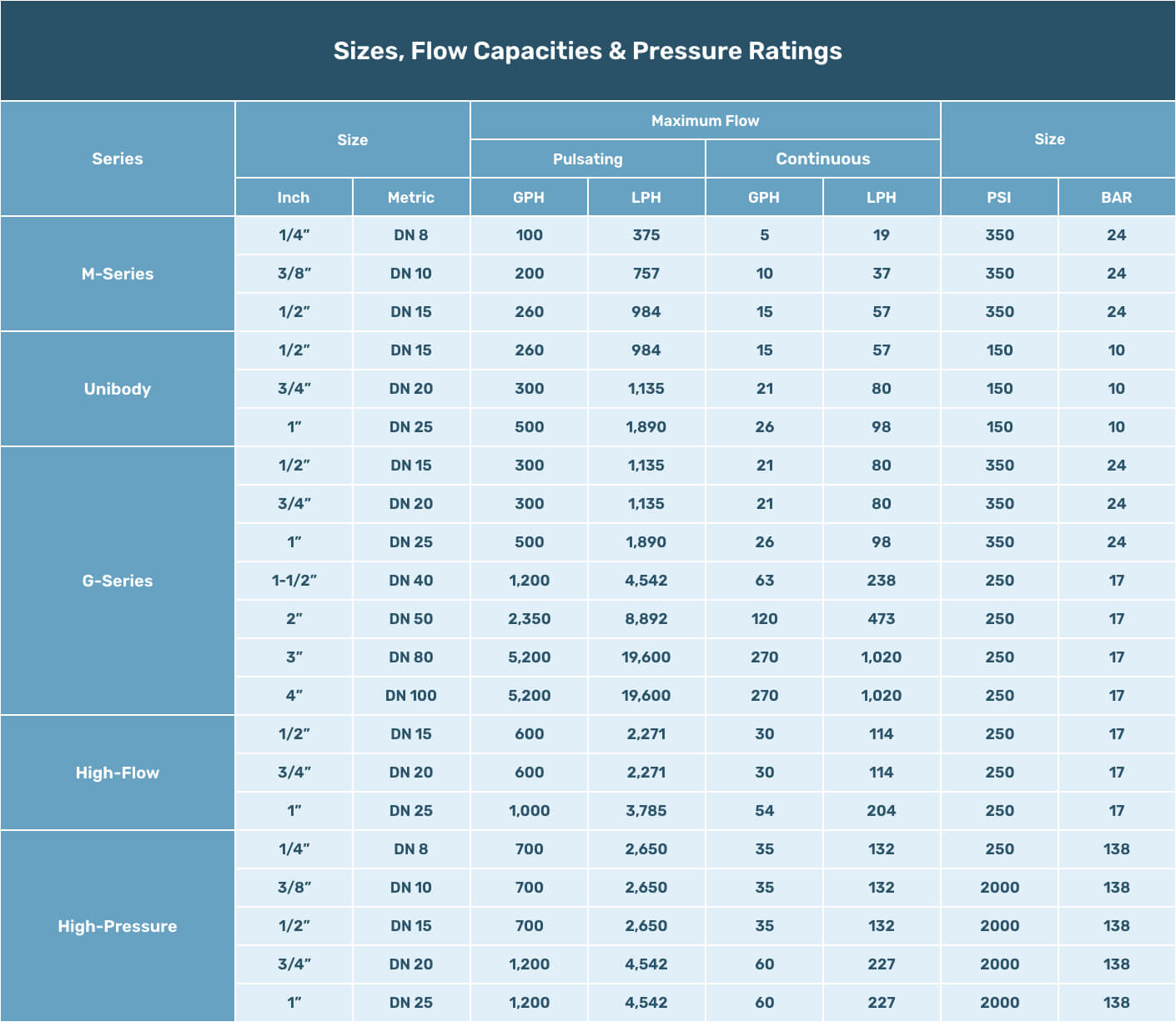

| Sizes, flowrange and pressure classifications | |||||||

| Sizes | Max Flow | Max pressure | |||||

| Pulsing | Continiously | ||||||

| Inch | Metric | GPH | LPH | GPM | LPM | PSI | BAR |

| 1/2″ | DN 15 | 320 | 1,211 | 17 | 63 | 350 | 24 |

| 3/4″ | DN 20 | 367 | 1,389 | 19 | 72 | 350 | 24 |

| 1″ | DN 25 | 462 | 1,798 | 24 | 90 | 350 | 24 |

| 1-1/2″ | DN 40 | 1,388 | 5,254 | 72 | 275 | 250 | 17 |

| 2″ | DN 50 | 1,533 | 5,803 | 80 | 302 | 250 | 17 |

| 3″ | DN 80 | 5,157 | 19,521 | 270 | 1,020 | 250 | 17 |

| 4″ | DN 100 | 5,157 | 19,521 | 270 | 1,020 | 250 | 17 |